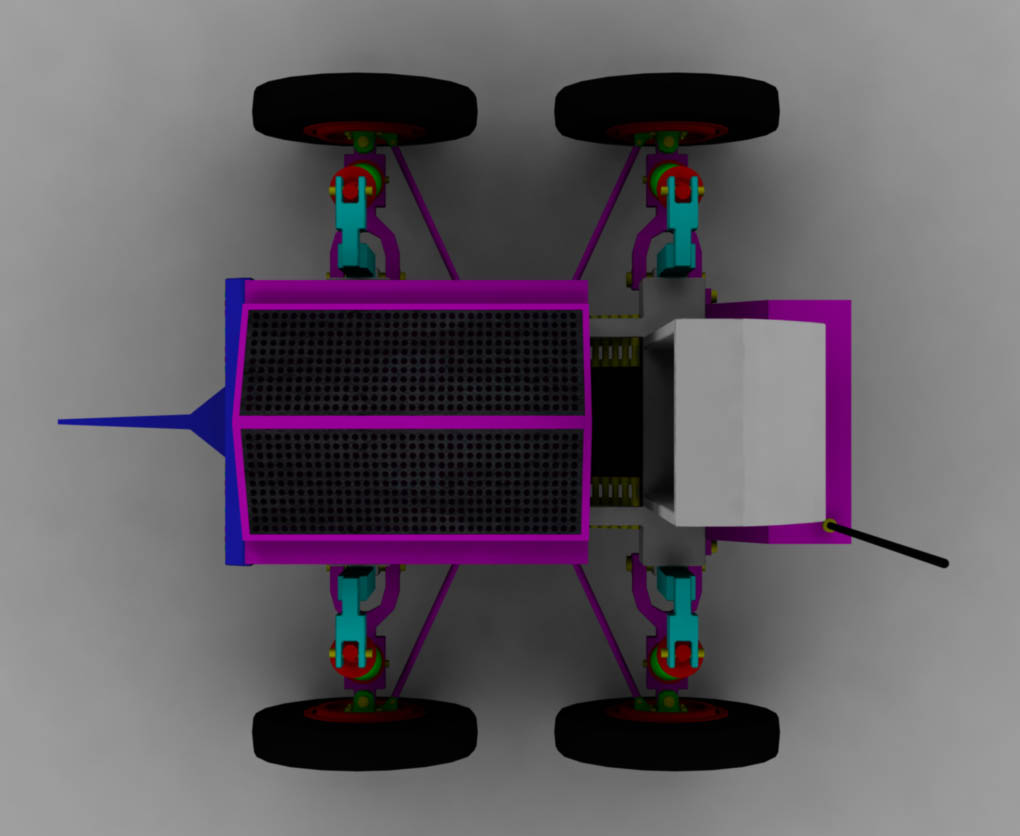

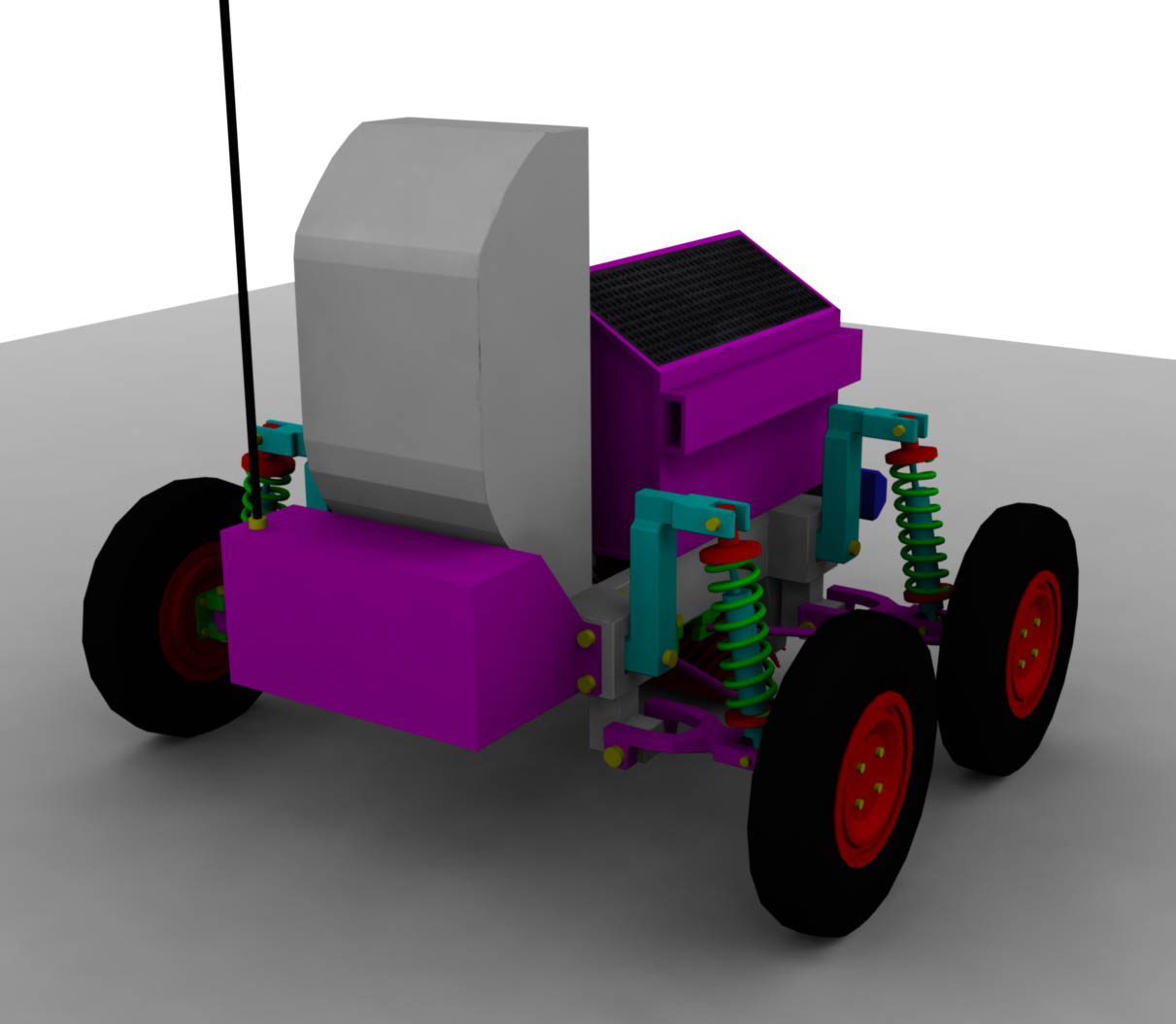

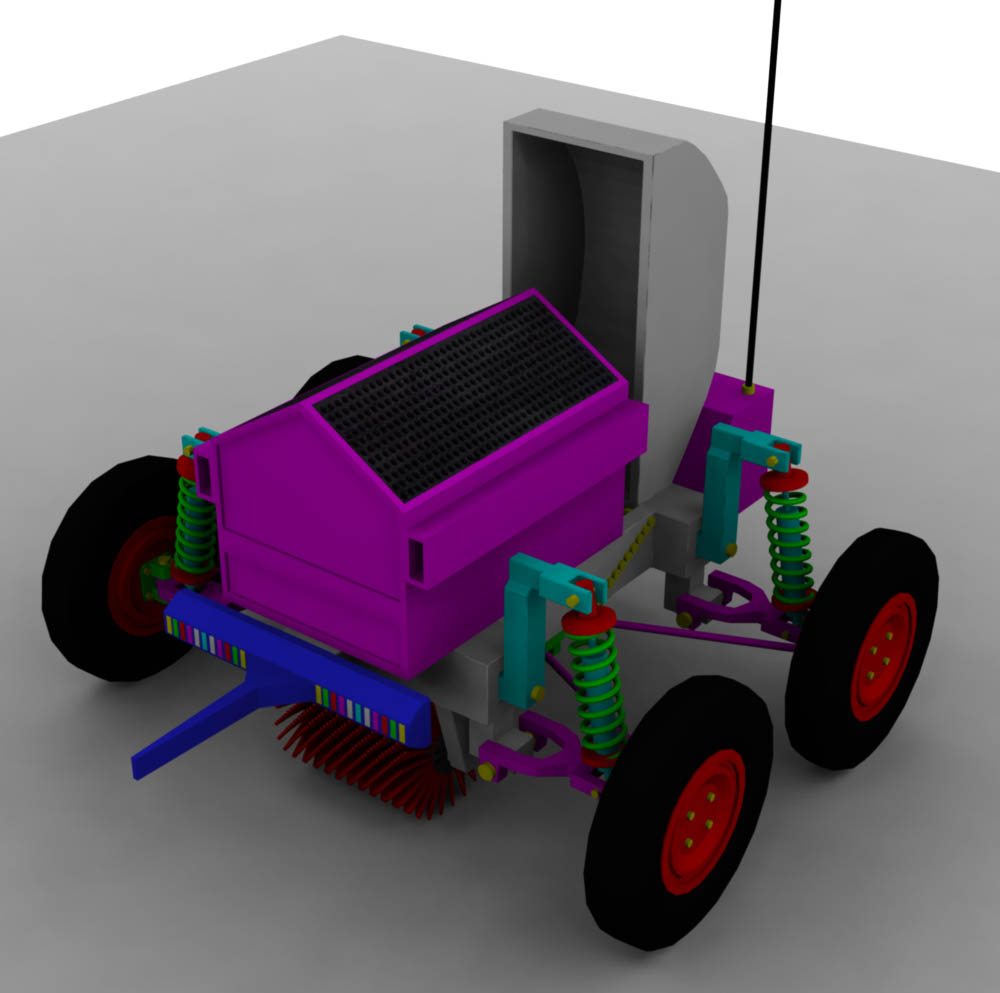

Came up with an idea for collecting regolith on the Moon.

The rover will ride across the surface with the sweeper spinning fast and moving the material to a fast moving conveyor that will accelerate the moon dust and slide it up the U-ramp and over the containment box. It will make quite the mess but be a very simple design. As long as most of the parts are sealed or covered with a non-degrading rubber like boot to keep the regolith from penetrating any joints or bushings it should last a long time with very little maintenance. The rover will have sensors and connectors on the front bumper to know where it is going and to connect to a terminal to recharge and deposit its cargo. The terminal will remove the cargo box much like a ground based garbage truck.