Space Station

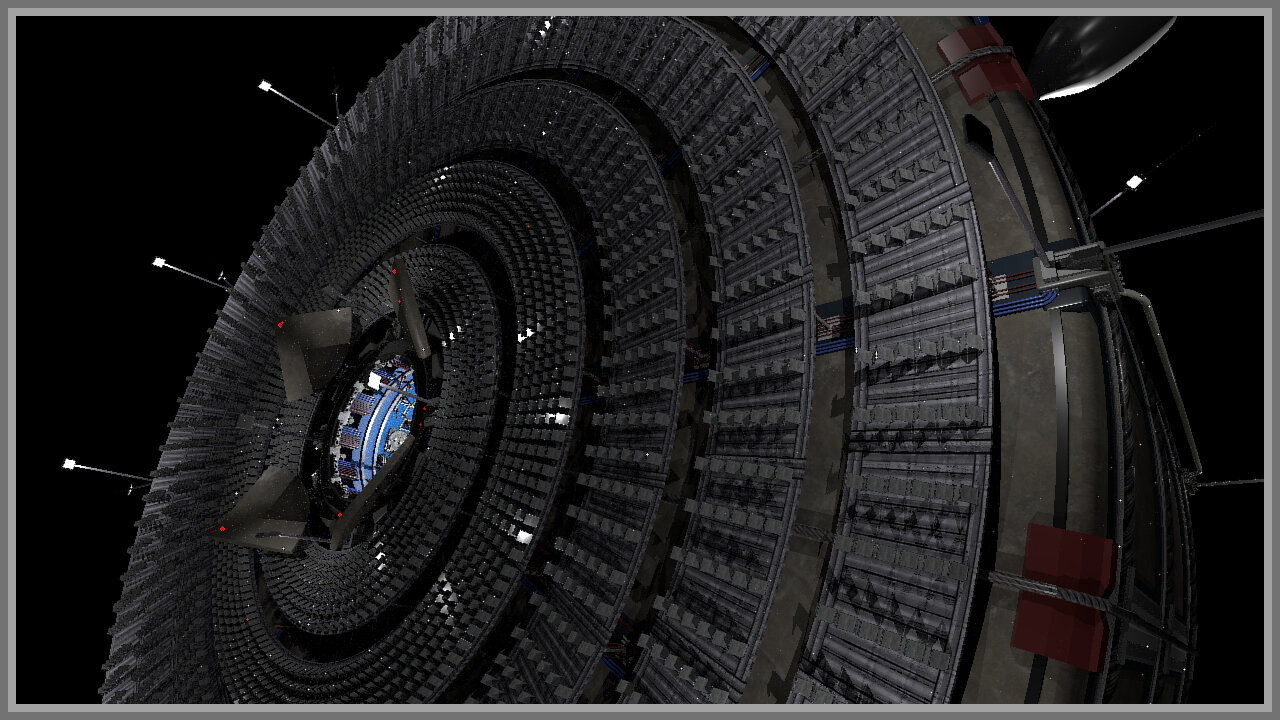

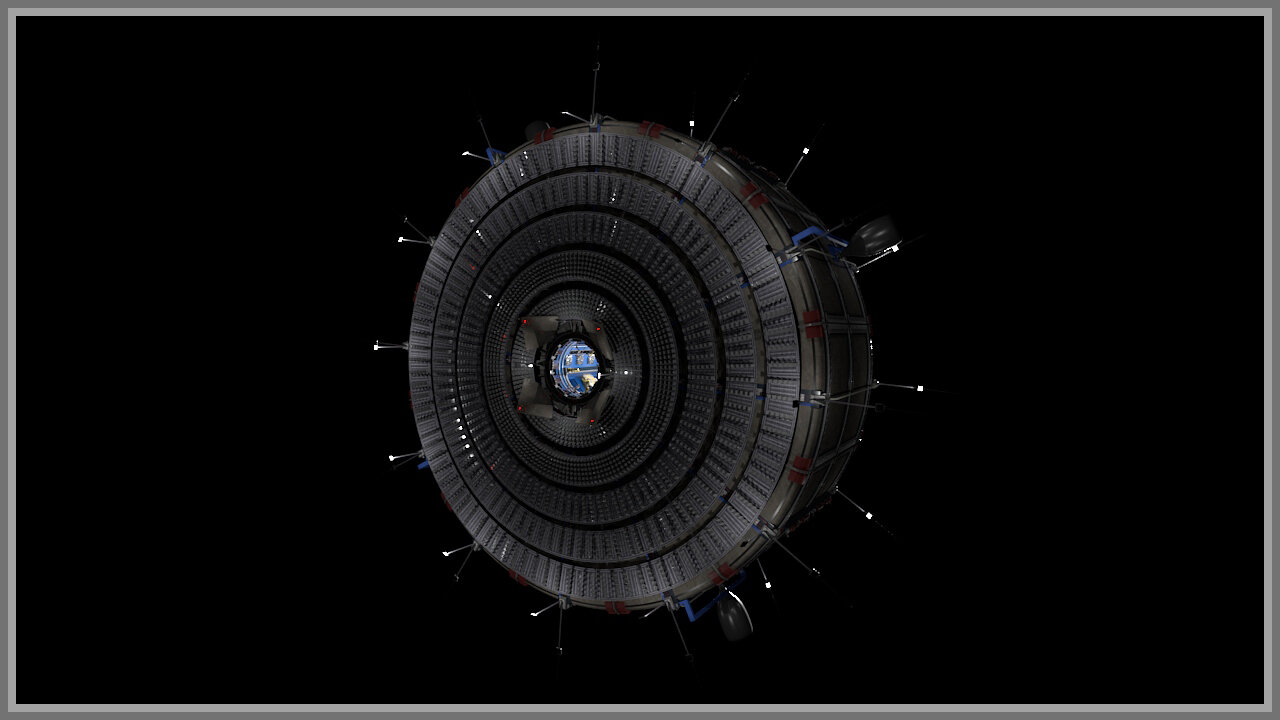

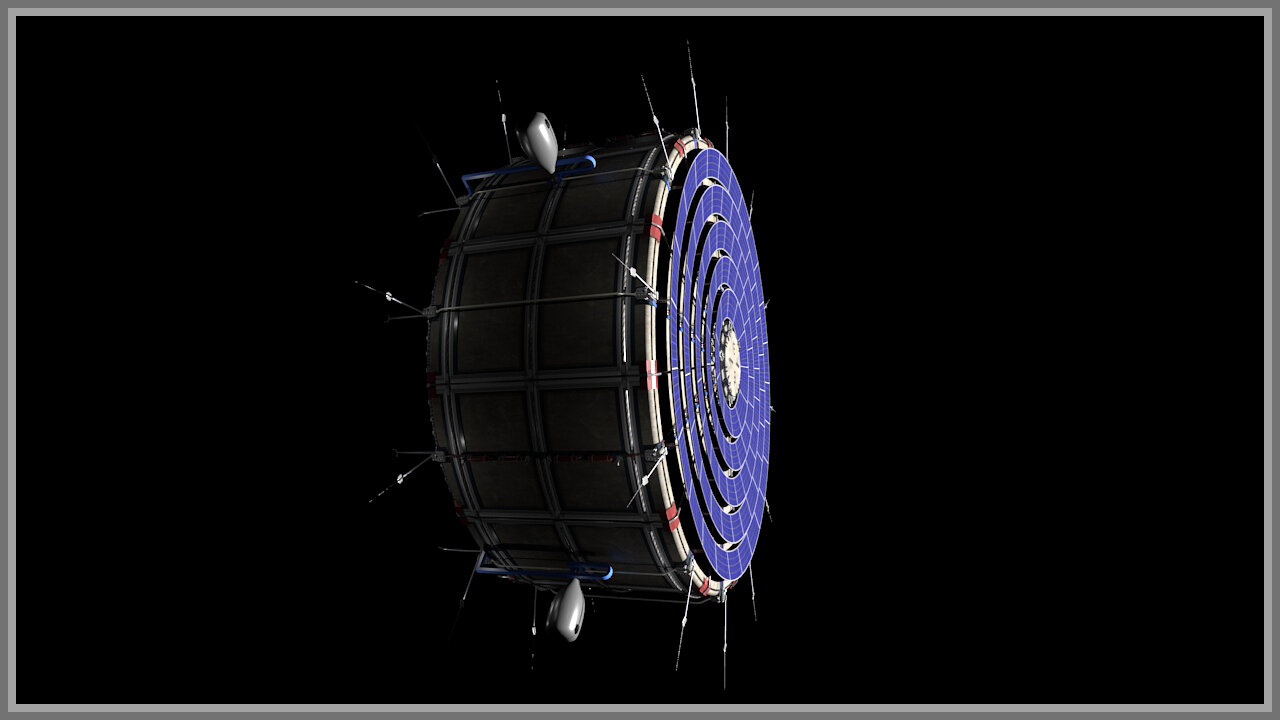

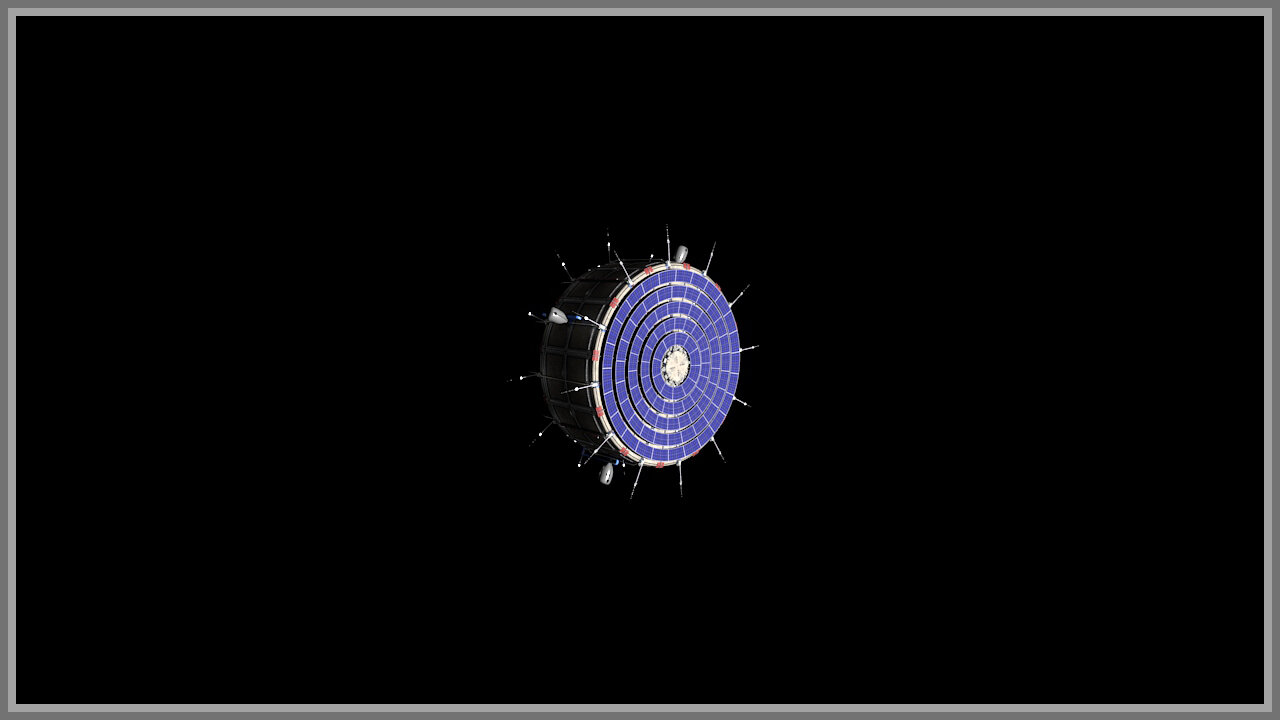

The planned dimensions of the rotating space station entail an outer shell radius of 450 feet (137.16 meters), with a 72.5-foot (22.1 m) radius designated for the central work area. The thickness of the station measures 390 feet (118.88 m). The main interior habitat will encompass an outer radius of 375 feet (114.3 m), an inner radius of 230 feet (70.104 m), and a depth of 300 feet (91.44 m). It is important to note that these dimensions are subject to change, depending on the characteristics of the selected structural material. To achieve a gravitational force of 1g (9.806 meters per second), the station will rotate at a speed of 2.797 rotations per minute, equivalent to 90 miles per hour (144.841 kilometers per hour), resulting in a 1.2g force at the outer perimeter of the station.

Structural Frame Development

Extensive research is currently underway to determine the ideal material for constructing the station's structure. The chosen material must possess high strength properties and effective radiation shielding. The estimated required amount of this material is approximately 140 million cubic feet (3,964,358.5 m3), considering both the habitat and the designated working areas. This poses a significant challenge as SpaceX's Starship, with a payload volume of 38,800 cubic feet (1098.6936 m3), would necessitate 3,609 launches to fulfill the material demand. However, ongoing advancements aim to overcome this obstacle by developing materials with a 30:1 expansion rate, significantly reducing the number of launches to approximately 120 (subject to weight restrictions). Assuming a hypothetical cost of $2 million per payload and a launch cost of $10 million per launch, the total expenditure for launching the base material of the station would amount to $1.35 billion. This estimate excludes the launches required to complete the entire station. Recent progress in the field suggests the potential use of high-strength foam as a viable structural material for the station.

The expanding material will be contained within lightweight tanks connected to a prebuilt manifold. Once all the tanks are interconnected, the station's template, a thin and highly malleable material, will be attached to the manifold's exit valve. The template will serve as a mold to hold and shape the expanding structural material, forming it into the desired station shape. To optimize the template design, it is advisable to incorporate structures and plumbing into the mold while ensuring minimal disruption to the filling process. The manifold will also house nitrogen tanks, facilitating the filling and pressurization of the voids inside the station, which will subsequently serve as living and working areas.

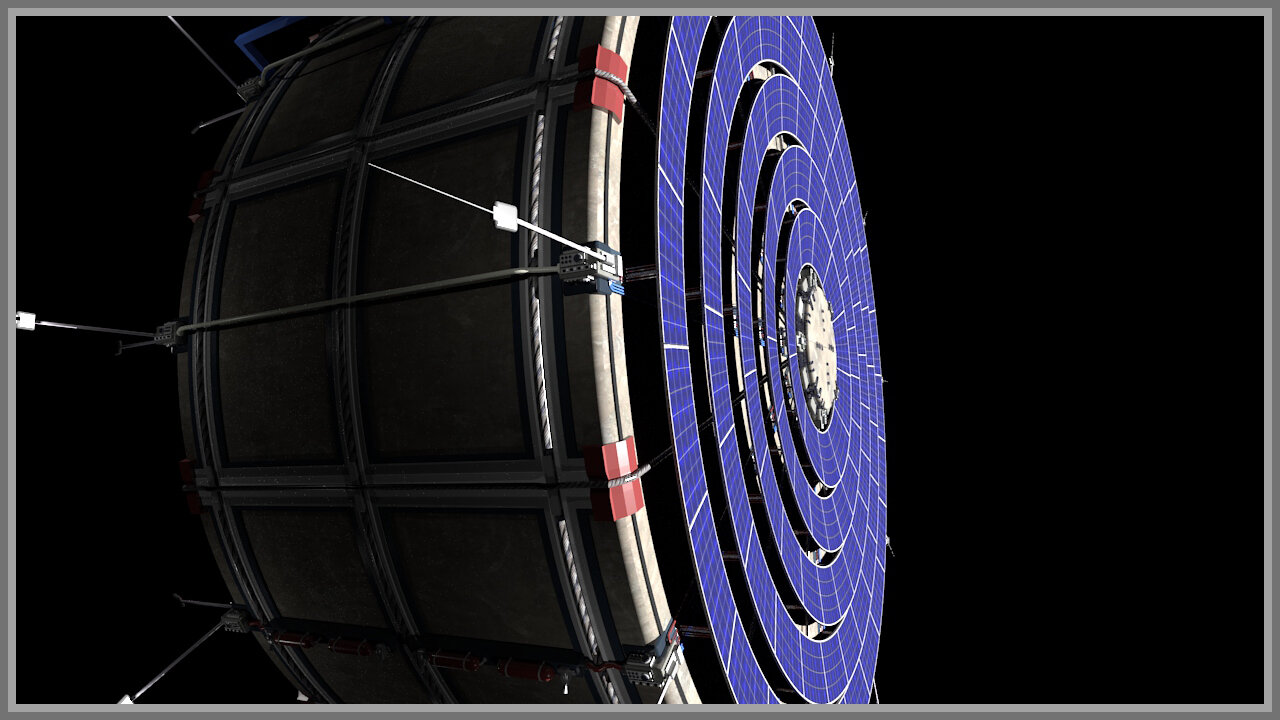

Adding Structural Integrity

Support for the station will be achieved by designing a structural ring within the central area and utilizing high-strength support wires wrapped around the outer perimeter. The support wires will rest on specialized pads, distributing the pressure evenly across the main structure. These wires will be adjustable at the center rings, similar to aligning a bicycle wheel. Additionally, a balloon-shaped ballast located along the outer edge will move across the station on a rail system. This ballast can adjust its weight distribution by emptying or refilling its bladder, thereby balancing the rotational forces acting on the structure. Four such ballasts will be incorporated, requiring the internal liquid to withstand extreme temperatures.

Energy

A total area of 550,000 square feet (51,096.7 m2) will be available for solar panels, capable of generating approximately 1.2 megawatts of electricity when the station is facing the sun. Coupled with battery storage, this initial power capacity should be sufficient for the station's energy needs. Alternative energy solutions, such as thermoelectric modules and small nuclear reactors, may be explored in the future. Additionally, the potential utilization of organic matter to produce methane for electricity generation or fuel production is being considered.

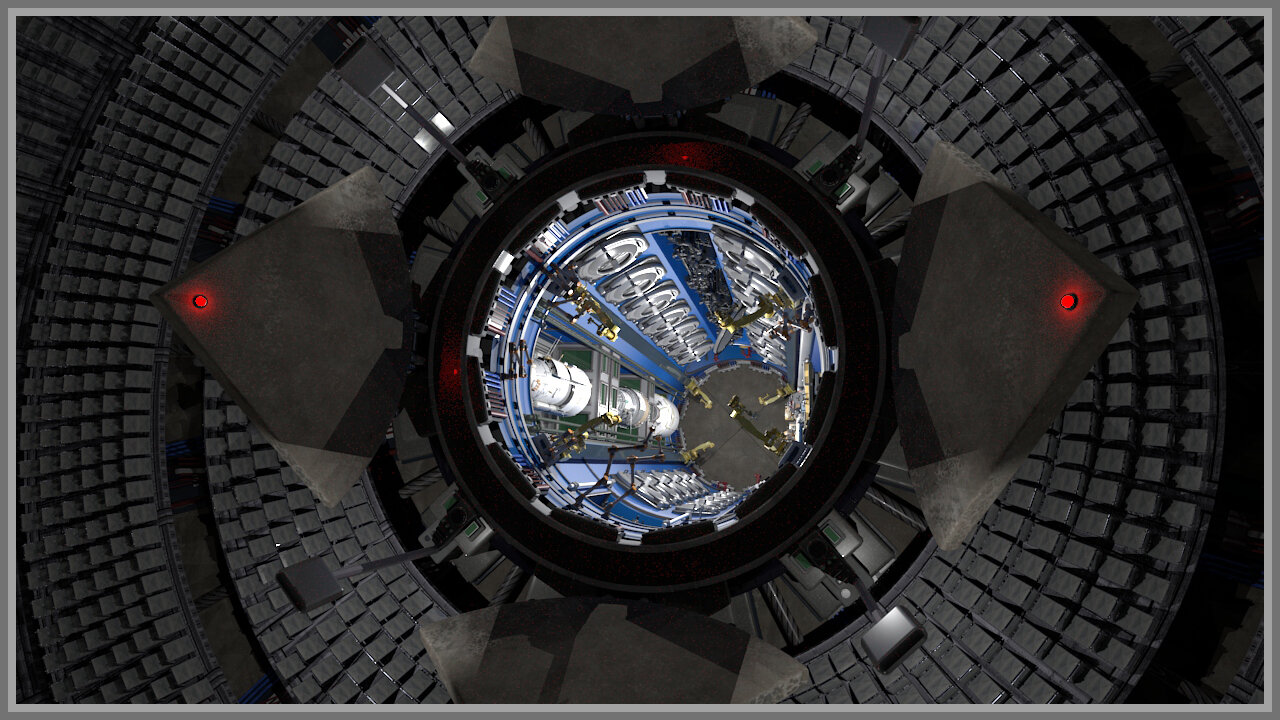

The station's bay doors, which will be divided into four sections and operated by electric motors, are preferably constructed using the same expanding material as the structure itself. These doors, situated approximately 74 feet (22.5552 m) from the rotational axis, will experience a centripetal acceleration force of 0.197g. Their primary function will be to shield the station from energetic particles. The dark side of the station will accommodate radiators and other essential instruments required for safe operation.

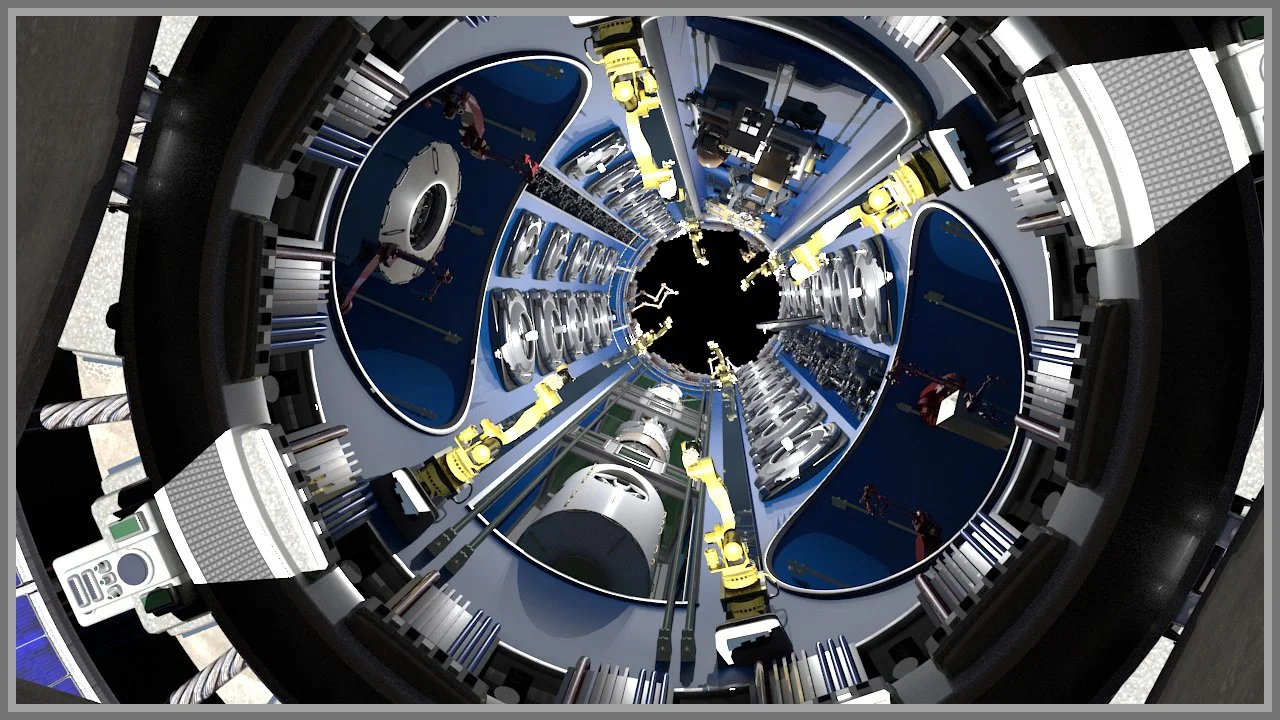

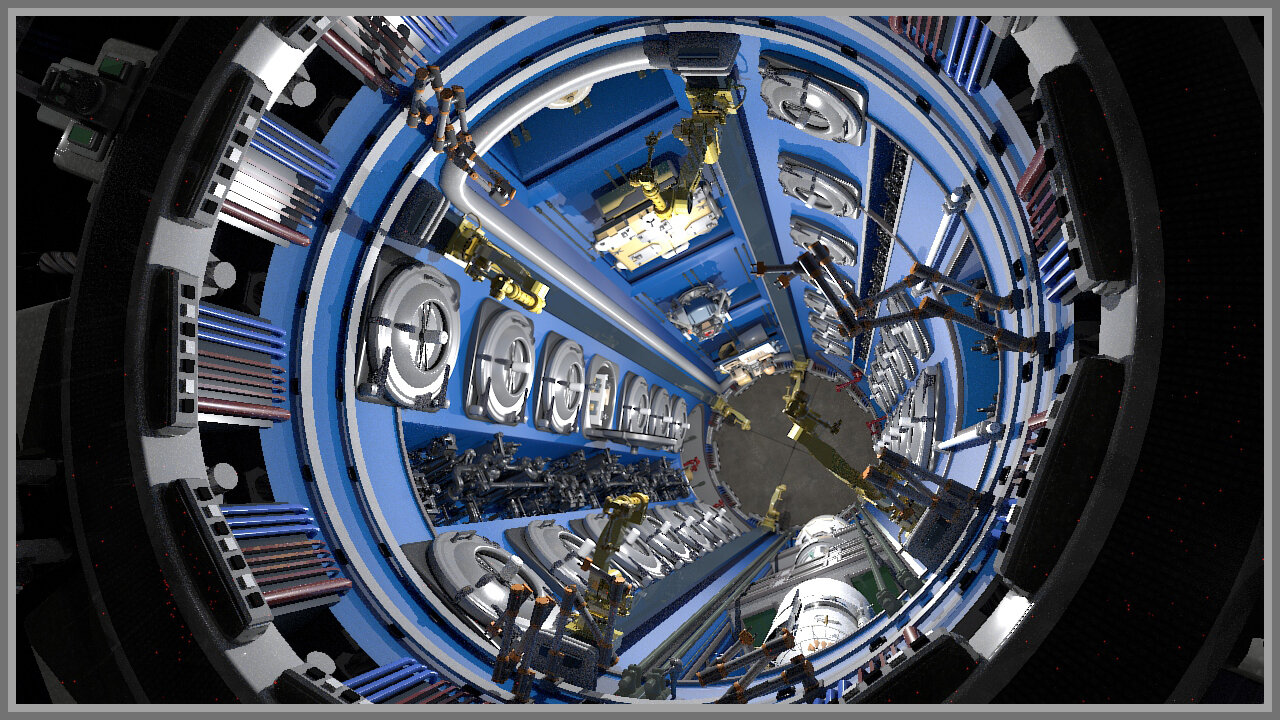

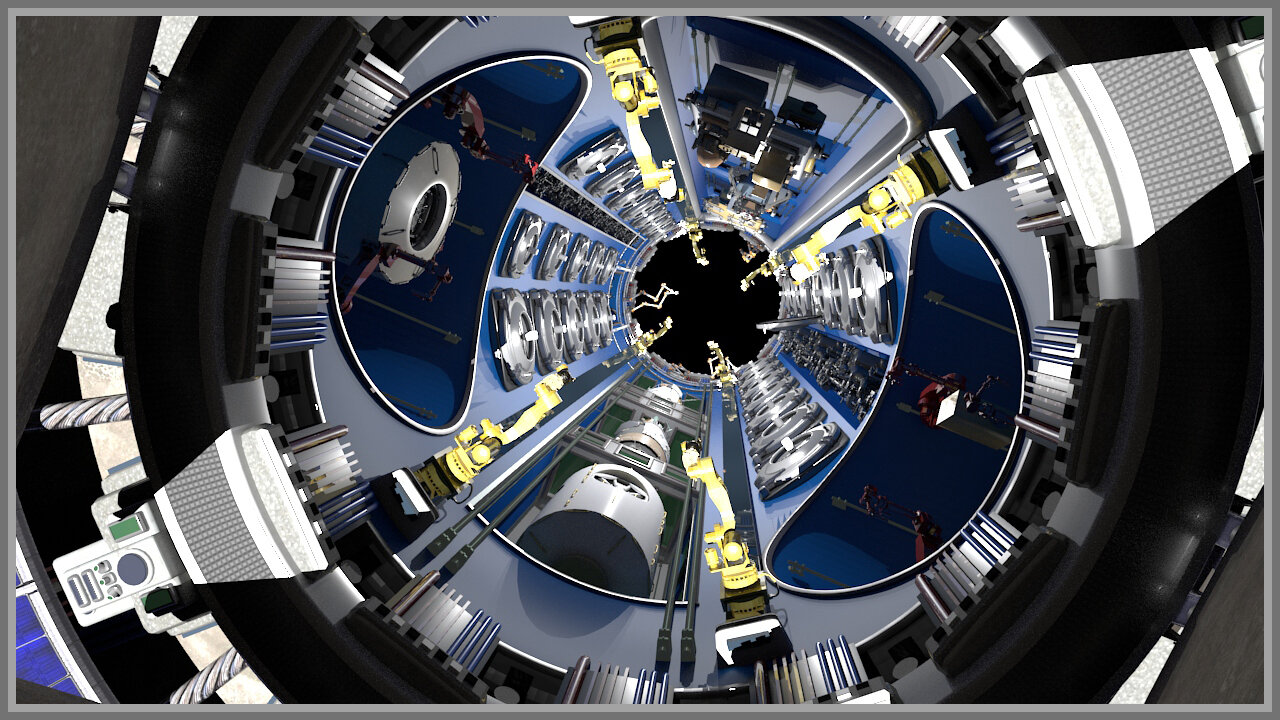

RTo facilitate the safe docking of spacecraft, robotic arms and advanced narrow AI systems will be employed within the central bay of the station. As a spacecraft enters the bay, the robotic arms will synchronize their rotation with the incoming craft, securely grasping it and aligning its rotation with that of the station. Secondary robotic arms will then maneuver the craft to the designated bay. The main bay will feature multiple docking and work areas, production facilities, and two primary docking regions for human-rated transports. Within the main bay, most tasks will be carried out remotely by robotics, controlled by personnel inside the station. The hatches leading to various-sized work areas can be rented or utilized for multiple purposes, accessible remotely by customers on Earth. The station's interior will comprise numerous rooms on different levels, including the main habitat, providing working environments in various gravity scenarios.

Habitat

The station is designed to accommodate 240 crew members, with three individuals per domicile. Each residence is strategically located at ground level, providing an environment with 1g of gravity. This approach aims to limit prolonged exposure to low-gravity environments, which could adversely affect the human body. LED cluster rings positioned along the hab's roof will serve as the primary light source for cultivating station food supplies. Due to space limitations, meat production will be restricted, potentially involving chickens, lab-grown meat, or even exploring insect consumption. A predominantly plant-based diet is expected, with luxury meat imports from Earth. Extensive efforts will be made to maximize limited space by employing vertical farming techniques, hydroponics, robotic plant maintenance, and harvesting, along with innovative farming practices utilizing unused areas within the station's interior walls.

The current hab layout represents an initial draft and is subject to modification. The aim is to create a small-town community atmosphere surrounded by abundant plant life and a pleasant stream for recreational swimming. The housing pods are envisioned as integral parts of the main structure, molded in tandem with the station's construction. Only utilities and finishing touches will be required to make them fully habitable. A river flowing along the station's edge will connect to the water pump and treatment facility. Water will be pumped to supply the entire station, stored in tanks, and released at regular intervals for irrigation purposes. This artificial rainfall will help maintain humidity levels, reduce dust, and ensure a cleaner environment. Furthermore, research will be conducted to mitigate static buildup and dissipate electrical charges effectively, potentially resulting in controlled thunderstorms in space. The main road for vehicles, bicycles, and pedestrians will run alongside the river, serving as a primary entrance to the hab.

The hab entrances will consist of two administration buildings. The main entrance will house the station control room and offices, while the secondary entrance will cater to remote operations. Additionally, there will be four warehouses dedicated to manufacturing, processing, and assembly. An environmental control building will regulate air quality and employ large fans to facilitate air circulation throughout the hab and station.

This rough draft of a vision for living and working in space is designed to generate conversation and interest. My rough estimate for the full construction and beginning of operations would cost $5 billion, only 3.5 percent of the cost of the International Space Station. The cost savings mainly comes through reduced launch costs of Starship and the ability to use common inexpensive tech designed for use in a gravity well. Although the station will not be fully self-sufficient it will be enough to limit the number of supply missions to the station.

Spending $5 billion on an investment needs to provide a healthy return. The primary purpose of the station will eventually be mining. Mainly processing material from the Moon and construction of new stations and structures. Several new companies are looking into mining material from the moon and we can assist in their production chain. Alternative revenue streams could stem from scientific research, dock and Hab space rental, refueling and resupply of spacecraft, tourism for the ultra-wealthy and fuel production using algae bioreactors.

Safety

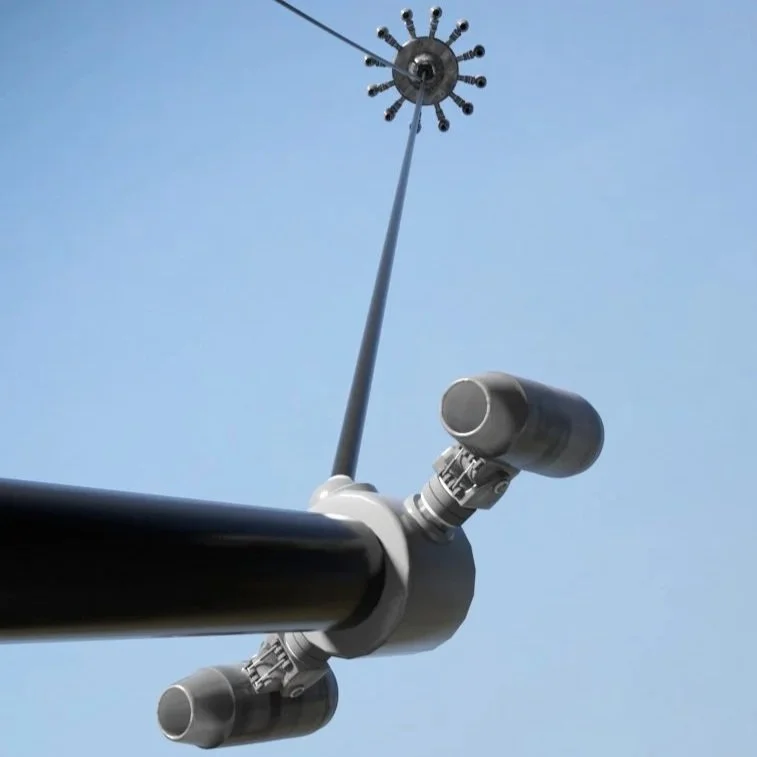

Safety measures will be paramount within the station. Each main section will be equipped with emergency supplies, vacuum suits, and communication tools. Small human-rated craft utilized for regular work activities will be modified to support survival in emergency situations. Vehicle flights will be automated, with advanced AI systems monitoring operations, aided by control room personnel. The station will feature advanced radar, communications, visual and optical sensors, and a swarm of drones propelled by pressurized gas and small ion drives. These drones will serve various functions, including debris capture, visual inspection, construction, and maintenance.

Take Action

Ready to take the next step? You can become a contributor to our cause, or participate yourself.